Enhance Your Process: Check Out the most up to date Innovations in Reputable Star Screen Devices

Exactly How Disc Screens Revolutionize Recycling Devices for Better Outcomes

The Capability of Disc Screens

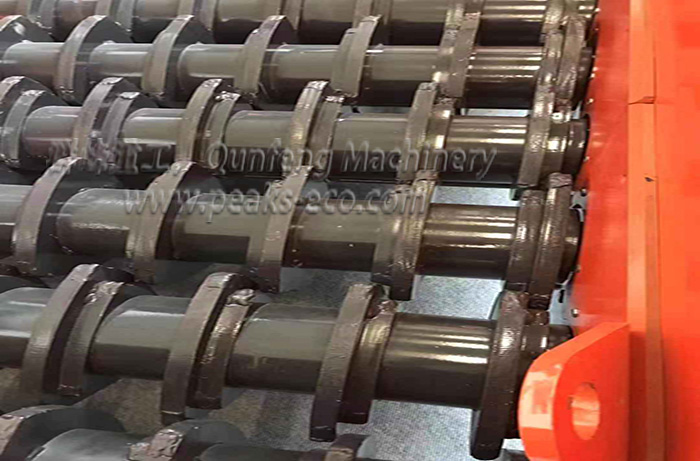

Disc screens are an integral part of reusing tools, effectively separating products based upon dimension and form to boost the overall recycling process. These screens are composed of a collection of rotating discs with specific openings that enable smaller sized materials to go through while larger products are maintained. The discs are placed at an angle, permitting gravity to help in the separation process.

The performance of disc displays hinges on their ability to precisely and successfully separate products, enhancing the high quality of recycled products. As the discs turn, the products are fed onto the display, and the smaller fragments drop with the openings. This separation procedure makes sure that materials of different dimensions are arranged right into distinct streams, allowing additional processing or direct reuse.

Advantages of Utilizing Disc Screens in Recycling

Among the crucial benefits of incorporating disc screens into recycling devices is their capability to dramatically improve the effectiveness and effectiveness of the reusing process (star screen). Disc displays provide a number of advantages that make them an important element in contemporary recycling centers

First of all, disc screens are extremely efficient in dividing products of different sizes. The revolving discs with precise spacing permit smaller sized particles to drop via, while larger materials are communicated onward. This results in a much more accurate and regular sorting of recyclables, minimizing the requirement for hands-on sorting and raising overall efficiency.

Second of all, disc displays are created to handle a wide range of products, including large and rough waste. Their durable construction and resilient materials make sure that they can withstand the severe conditions of the reusing process, lessening downtime and upkeep costs.

Moreover, disc screens have a high throughput ability, enabling them to refine huge volumes of waste in a shorter quantity of time. This not just boosts performance but also permits recycling facilities to meet the growing need for recycled materials.

Another advantage of disc displays is their capacity to reduce contamination in the last arranged materials. By successfully getting rid of undesirable materials, such as plastics or paper, disc screens aid produce higher-quality recyclables, which consequently enhances their market price.

Exactly How Disc Screens Improve Effectiveness in Arranging

Incorporating disc screens right into reusing tools not only offers various advantages but it additionally significantly boosts the effectiveness of the sorting process. Disc screens are designed to different materials based upon their size, form, and density, causing an extra effective and precise sorting procedure.

Among the crucial methods which disc screens enhance effectiveness is with their ability to handle a high volume of product. With their rotating discs, these screens can swiftly refine big quantities of recyclables, lowering the time and effort needed for arranging. This raised throughput permits reusing facilities to sort and procedure materials at a quicker rate, ultimately increasing overall performance.

Additionally, disc screens enhance effectiveness by successfully dividing various sorts of products. The discs on the screen have actually purposefully placed openings that allow smaller sized materials to pass through while bigger products are redirected to one more conveyor or sorting system. This makes certain that each product stream is correctly arranged, lowering the danger of contamination and boosting the high quality of the recycled products.

Furthermore, disc screens are geared up with advanced modern technology that allows exact product splitting up. By readjusting the rate, angle, and spacing of the discs, operators can personalize the arranging procedure to meet certain demands. This degree of control makes sure that materials are precisely arranged, taking full advantage of the recovery of useful sources and reducing waste.

Enhancing the High Quality of Recycled Products With Disc Screens

With the assimilation of disc screens right into recycling tools, Your Domain Name the high quality of recycled materials can be dramatically boosted. Disc displays are innovative equipments that play a critical function in the reusing procedure by efficiently dividing different sorts of products. These screens consist of multiple rotating discs with details opening dimensions, permitting smaller sized fragments to fail while bigger materials proceed along the conveyor belt. By utilizing disc screens, recyclers can achieve a greater level of pureness in their end items.

One of the essential benefits of disc displays is their capacity to eliminate contaminants such as plastic movie, paper, and other non-recyclable products. The turning discs successfully different these impurities from the recyclable products, resulting in a cleaner and purer final result. This not only enhances the overall high quality of recycled materials yet additionally minimizes the threat of contamination in downstream procedures.

Furthermore, disc displays can boost the quality of recycled materials by successfully dividing various kinds of recyclables based upon their shapes and size. This allows recyclers to produce products with regular particle sizes, which remain in high need by producers. Consistency in bit size boosts the performance of recycled materials in various applications, such as plastic molding and paper manufacturing.

The Future of Recycling Equipment: Disc Screens

The continued improvement of reusing devices innovation is paving the method for the future of disc screens. These ingenious devices are set to change the reusing sector by improving effectiveness and increasing the quality of recycled materials.

Among the essential advancements in disc screen innovation is the combination of expert system (AI) and artificial intelligence algorithms. These developments make it possible for disc displays to adjust and enhance their efficiency based on real-time data. By evaluating the structure and characteristics of inbound products, disc screens can change their settings to attain the very best possible separation and sorting outcomes.

Another location of focus for the future of disc screens is their capacity to handle a broader range of materials. Conventional disc screens were mostly designed for sorting paper, cardboard, and plastics. Nonetheless, with the boosting demand for reusing various kinds of waste, there is check my source a need for disc displays that can efficiently deal with materials such as glass, metals, and digital waste.

In addition, the future of disc screens exists in their ability to minimize upkeep and functional prices. Producers are investing in r & d to produce more durable and durable screens that need minimal upkeep. In addition, improvements in automation and remote surveillance modern technologies will make it possible for drivers to remotely keep track of and control disc screens, decreasing the requirement for on-site personnel.

Final Thought

Finally, disc displays have transformed recycling equipment by enhancing performance in arranging and improving the top quality of recycled products. Their functionality enables for reliable separation of different materials, resulting in much better outcomes and increased productivity in the reusing procedure. As the future of reusing equipment, disc screens provide appealing improvements in the field, leading the way for an extra lasting and reliable recycling industry.

Disc screens are an indispensable component of reusing equipment, efficiently dividing materials based on dimension and shape to improve the general recycling procedure (star screen). These screens are composed of a series of rotating discs with details openings that permit smaller products to pass via while bigger products are maintained. The discs on the display have actually strategically positioned openings that allow smaller materials to pass via while bigger products are rerouted to an additional conveyor or click over here sorting system. Disc displays are innovative equipments that play a critical duty in the reusing process by efficiently dividing different types of materials.In conclusion, disc screens have actually reinvented recycling tools by improving efficiency in sorting and improving the high quality of recycled materials